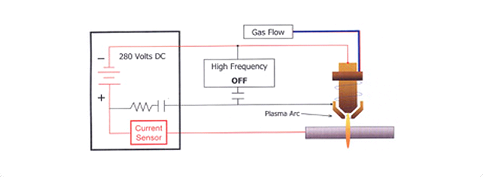

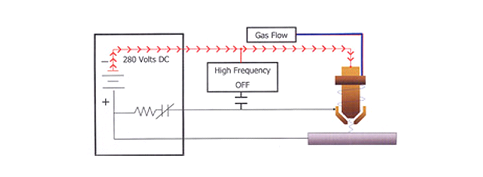

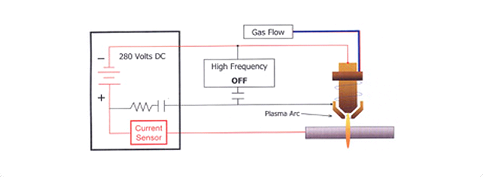

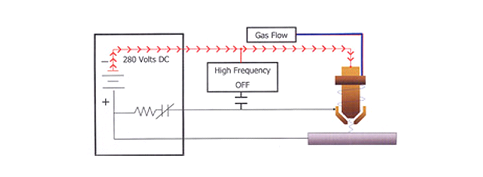

A start input signal is sent to the power supply. This simultaneously activates the open circuit voltage and the gas flow to the torch (see Figure 2). Open circuit voltage can be measured from the electrode (-) to the nozzle (+). Notice that the nozzle is connected to positive in the power supply through a resistor and a relay (pilot arc relay), while the metal to be cut (workpiece) is connected directly to positive. Gas flows through the nozzle and exits out the orifice. There is no arc at this time as there is no current path for the DC voltage.

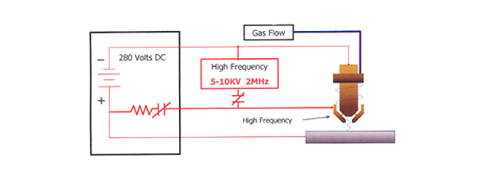

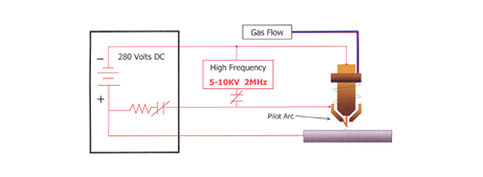

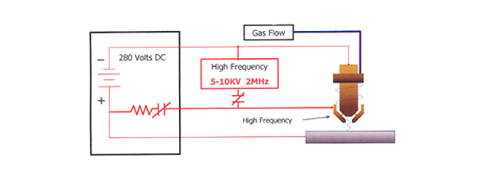

After the gas flow stabilizes, the high frequency circuit is activated. The high frequency breaks down between the electrode and nozzle inside the torch in such a way that the gas must pass through this arc before exiting the nozzle. Energy transferred from the high frequency arc to the gas causes the gas to become ionized, therefore electrically conductive. This electrically conductive gas creates a current path between the electrode and the nozzle, and a resulting plasma arc is formed. The flow of the gas forces this arc through the nozzle orifice, creating a pilot arc.

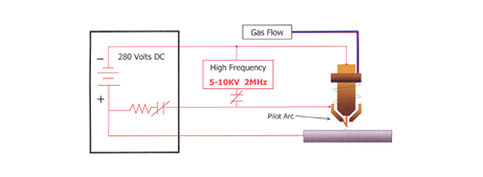

Assuming that the nozzle is within close proximity to the workpiece, the pilot arc will attach to the workpiece, as the current path to positive (at the power supply) is not restricted by a resistance as the positive nozzle connection is. Current flow to the workpiece is sensed electronically at the power supply. As this current flow is sensed, the high frequency is disabled and the pilot arc relay is opened. Gas ionization is maintained with energy from the main DC arc.

The temperature of the plasma arc melts the metal, pierces through the workpiece and the high velocity gas flow removes the molten material from the bottom of the cut kerf. At this time, torch motion is initiated and the cutting process begins.