History of

CNC PLASMA CUTTER

?

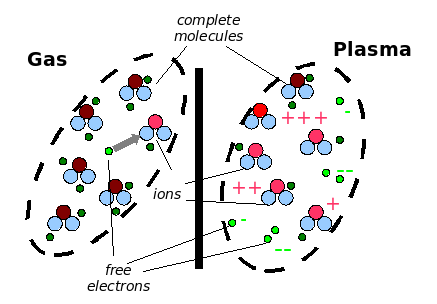

The plasma cutting grew out of plasma welding more than 50 years ago during the height of World War II. In the effort of seeking a more efficient method to join light metals for faster aircraft production, a new welding process was born. An electric arc was used to melt the metal, and an inert gas was used to shield around the arc and the pool of molten metal. The objective was to prevent the oxidation of molten metal by displacing the air.

Over next several years, the plasma cutting process has drastically developed with further testing and improvements. At this time, it was discovered that by restricting the opening through which the inert gas passed, the heat produced by the process was tremendously elevated. At the same time, the smaller opening caused the flow of gas to speed up dramatically, ultimately blowing out a channel in the work.

In the mid sixties, plasma arc cutters began seeing commercial use with everyday applications as the process became a bit more common even though it was still extremely expensive to carry out. Large factories were able to afford the advanced technology and thrived on the ability to cut metal quickly and more efficiently.

As with other machine tools, CNC (computer numerical control) technology was applied to plasma cutting machines in the late 1980s into the 1990s, but only in the past decade has it become affordable enough for the small shop. giving plasma cutting machines greater flexibility to cut diverse shapes "on demand" based on a set of instructions that were programmed into the machine's numerical control.

The plasma cutting process, itself, is capable of almost surgical precision. It is the human hand that guides a manual plasma cutting torch that is responsible for the roughness sometimes seen in plasma cut pieces.

Today's CNC plasma cutting systems typically use the operator's personal computer to create the shapes to be cut and control the cutting machine. The resulting shapes are smoother than would be possible with a bandsaw, and can include intricate curves, inside cuts, and sharp corners.