COMPARISON BETWEEN

VARIOUS CUTTING METHOD

Quality of cut| Flame | Plasma | Laser | Water Jet | |

|---|---|---|---|---|

| Heat affected area | Large | Small | Very Small | - |

| Workload for dross clean up | Large | Almost no dross | Almost no dross | No dross |

| Material | Low carbon steel | Low carbon steel, stainless steel, aluminum and other conductive metal material | Low carbon steel, stainless steel, aluminum and non-metallic material (not reflective of light) | Carbon steel, low alloy steel, non-ferrous metal, stainless steel, paper, plastic, ceramics, composite, food (except abrasive) |

| Quality of cutting | Normal | Fine | High precision | High precision |

| Cutting Seam | 2-6mm | 2-6mm | 0.1-1mm | 0.1 - 0.3mm (water only) 0.8mm (abrasive) |

| Cutting Speed | Slow | Fast | Fast ( for sheet material ) | Slow |

|---|---|---|---|---|

| Speed ( mm/min) | 100 - 800 | 600 - 6000 | 800 - 10000 | 600 - 5000 |

| Time for perforation | Preheat time very long | Very fast | Fast | Fast |

| Cutting range for low carbon steel | 5 – 500mm | 1 – 50mm | 0.5 – 20mm | 0.5 – 250mm |

| Cutting range for stainless steel, aluminum | Not suitable to use | 1 – 150mm | 0.5 - 20mm | 0.5 – 250mm |

| Initial capital investment required | Low | Medium | High | Higher than Plasma |

|---|---|---|---|---|

| Rework processing for dross | needed | - | - | - |

| Cutting cost | Low | Lower than flame cutting | Higher than plasma cutting | Higher than plasma cutting |

| Maintenance cost | Low | Simple | High | Medium |

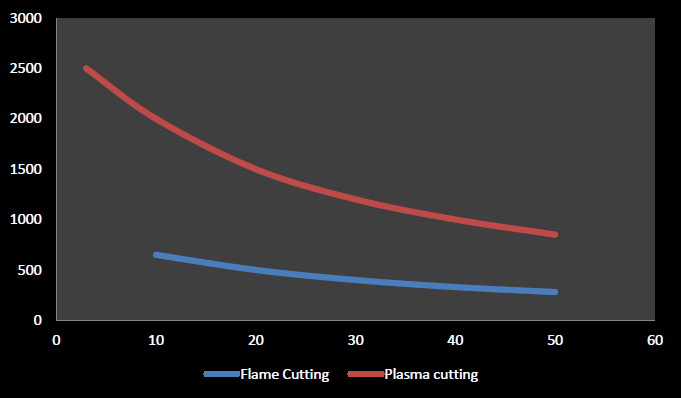

Comparison of the speed for plasma cutting and flame cutting

| Process | Shield | USED FOR | ADVANTAGES |

|---|---|---|---|

| 02 | Air | Mild Steel Precision 50-300 amps and High Speed Oxygen process | Weld ready cut surface |

| 02 | 02 | Mild Steel Precision at 30 amps | Weld ready cut surface |

| H2O | H2O | Precision Aluminum and Stainless Steel | Best cut quality on stainless and aluminum to 3/4" Better parts life than air |

| N2 | N2 | Conventional thin non-ferrous | Better cut surface than air on non-ferrous Faster cutting on thicker SS and aluminum |

| H35 | N2 | > 1/2" aluminum > 3/4" stainless | Weld ready cut surface H35 = 65%Ar / 35%H2 |

| Air | Air | Conventional mild steel | Economical cost of operation Good cut quality |

| Air | Air | Conventional non-ferrous | Economical cost of operation |